Silicagel

Silica gel is often used in the pharmaceutical, cosmetic and food & beverage industries. The primary function of silica gel is to protect the packaged content against internal moistening by controlling and/or degreasing the moisture level within the closed package. Silica gel is a safe product since it is non-corrosive and non-toxic by nature. Therefore silica gel has received US government approval for use in food and drug packaging.

Silica Gel is designed to control moisture levels within packaged products due to (1) its adsorption capability which occurs due to Van der Waals interactions and (2) capillary condensation at high humidity. Silica gel has an amorphous micro-porous structure (3-60 angstrom) with an interconnected pore distribution. The interconnected hydrophilic pores form a vast surface area which attracts and hold water through adsorption and capillary condensation. Silica gel functions like a sponge with millions of interconnected microscopic pores.

Productie

Silica gel consists of irregularly shaped and porous particles and is a form of silicic acid. The raw materials used in its production are mainly sodium silicate and sulphuric acid. These chemicals are made to undergo a chemical reaction which takes place under certain specific conditions. The result is a hard, translucent material made from amorphous silicate, pure silicon dioxide with a very high SiO2-content.

Silica gel is broken down into granules and then washed, aged, and dried to produce the highly porous material. The properties of silica gels are a result of the size and state of aggregation of the randomly linked spherical polymerised silicate particles (SiO2) and their surface chemistry. To achieve this, silica gel manufacturers control the conditions of the washing, ageing, and drying processes to manipulate the most important physical parameters such as pore size, porosity, and surface area.

Features

Silica gel is inert and compatible with many kinds of materials, except for strong alkaline substances and hydrofluoric acid. Silica gel is odourless, non-toxic, does not release fumes and does not corrode metal. The very extensive surface in the interior of the silica gel particles consists of a vast network of microscopic pores which can attract and hold an amount of moisture of up to 36% of their own weight without losing their structure.

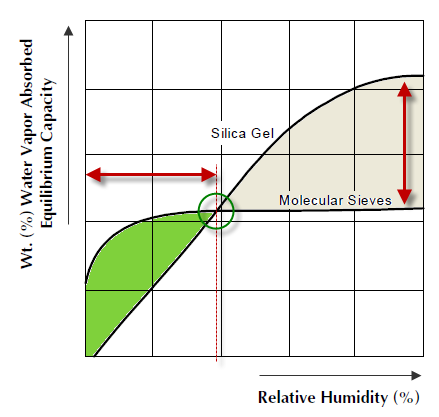

Silica gel is extremely efficient at temperatures below 25°C, but will lose some of its adsorption capacity as temperatures begin to rise. Even under very low humidity conditions a small amount of water vapour will be adsorbed in the interconnected microscopic pores. As humidity increases, the larger pores will begin to fill. The adsorption force is less than for molecular sieves (zeolite compounds), resulting in a lower adsorption capacity at low concentrations of adsorbents (see chart below). On the other hand, at higher concentrations of adsorbents, the adsorption capacity is higher than for zeolite compounds due to the higher internal pore volume. One of the unique features of silica gel is its nature to remain dry at maximum capacity. Silica gel will also adsorb more moisture with increasing time.

Silica gel vs. molecular sieve

The chart below shows the characteristic curves for the adsorption of water on silica gel and on molecular sieves. It shows the weight percentage adsorbed versus the relative humidity in contact with the silica gel and the molecular sieve. The given example (demo chart) demonstrates the difference between the water vapour adsorption rate of silica gel and molecular sieves.

Silica-gel-vs-mol-sieve.png

Silica-gel-vs-mol-sieve.png

The chart:

- The chart is for demonstration purposes only. Nevertheless both curves are trustworthy for this purpose.

- The structure of molecular sieves provides a higher capacity for water adsorption than silica gel at low relative humidities.

- Molecular sieves are preferred for systems that must produce very low relative humidities.

- Silica gel has superior characteristics at high relative humidities.

Use of silica gel

Desiccant bags and container inserts, filled with highly active drying agents (even combinations of silica gel and molecular sieves), offer an ideal solution for the protection of moisture sensitive products in an effective and environmentally friendly way.